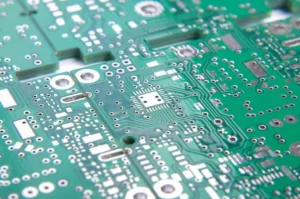

Flexible PCB, also called flex circuit board or FPCB, is a type of printed circuit board designed to bend and twist without breaking. Unlike rigid PCBs, flexible PCBs use thin and lightweight materials, making them widely used in modern electronics where space-saving, durability, and flexibility are critical. In this article, we will explore what flexible PCB is, how it is made, its types, benefits, and applications.

What is Flexible PCB

A flexible PCB is a circuit board made with flexible base materials like polyimide or polyester films. It allows electronic circuits to bend, fold, and twist while maintaining excellent electrical performance. Because of its lightweight and thin design, it is perfect for compact devices such as smartphones, wearables, and medical equipment.

Types of Flexible PCB

There are several types of flexible PCBs depending on design and structure:

- Single-sided flexible PCB – contains only one layer of conductive material, suitable for simple circuits.

- Double-sided flexible PCB – has conductive layers on both sides, offering higher circuit density.

- Multilayer flexible PCB – integrates multiple conductive layers for complex applications.

- Rigid-flex PCB – combines rigid and flexible areas, ideal for devices needing both durability and flexibility.

Materials Used in Flexible PCB Manufacturing

The key materials for flexible PCB production include:

- Base material (Polyimide/Polyester films) – provides flexibility and insulation.

- Copper foil – serves as the conductive layer.

- Adhesives – bond copper and base film together.

- Protective layer (Solder mask/Coverlaylay) – prevents oxidation and protects the circuit.

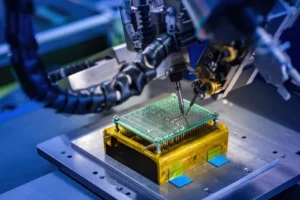

How Flexible PCB is Made

The manufacturing process of a flex PCB involves:

- Designing the circuit layout using CAD software.

- Laminating copper foil onto the flexible base film.

- Etching the copper layer to form circuit patterns.

- Applying coverlay or solder mask for protection.

- Drilling and plating vias if multilayer connections are needed.

- Testing electrical performance before delivery.

Advantages of Flexible PCB

Flexible PCBs offer several benefits compared to rigid PCBs:

- Lightweight and space-saving.

- Can bend and fold to fit into compact devices.

- High durability under vibration and mechanical stress.

- Better heat dissipation and reliability.

- Reduces assembly time and cost in complex designs.

Applications of Flexible PCB

Flexible PCBs are widely used in industries such as:

- Consumer electronics – smartphones, tablets, cameras, wearables.

- Automotive electronics – dashboards, airbags, sensors, LED lighting.

- Medical devices – pacemakers, hearing aids, diagnostic equipment.

- Industrial equipment – robotics, sensors, automation systems.

- Aerospace and defense – satellites, navigation systems, avionics.

Flexible PCB vs Rigid PCB

The major differences include:

- Structure – flexible PCB uses polyimide films, rigid PCB uses FR4.

- Flexibility – flex PCBs can bend, rigid PCBs cannot.

- Applications – flexible PCBs suit compact and dynamic devices, while rigid PCBs fit static and larger circuits.

- Cost – flexible PCBs are generally more expensive due to materials and process.

Future Trends of Flexible PCB

With the rapid growth of 5G, IoT, and wearable electronics, flexible PCBs will continue to dominate the market. They are essential for next-generation devices where lightweight, compact size, and high performance are required.