The Silent Revolution: How PCBA Shaped the Future of Electronics

The hum of machinery fills the air as a robotic arm delicately places a tiny chip onto a green circuit board. This scene, repeated millions times daily in factories worldwide, represents the heartbeat of modern technology—Printed Circuit Board Assembly (PCBA). From smartphones to medical devices, PCBA technology quietly underpins our digital lives.

The Birth of a Digital Era

In the early days of electronics, bulky components were manually soldered onto boards, a labor-intensive process prone to errors. The breakthrough came with Surface-Mount Technology (SMT), enabling machines to place components with micron-level precision. Today, SMT allows for the creation of ultra-compact PCBA designs, such as those in wearable devices, where space is at a premium.

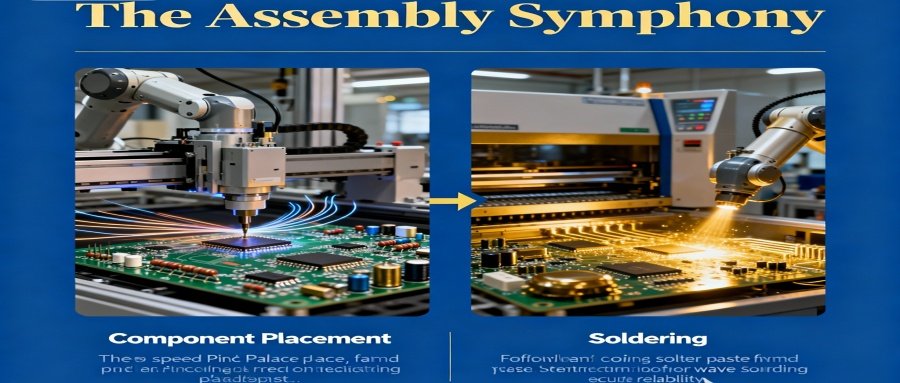

The Assembly Symphony

The PCBA process unfolds like a well-orchestrated symphony:

- Component Placement: High-speed pick-and-place machines arrange resistors, capacitors, and integrated circuits onto the PCB. Imagine a robotic ballet where each movement is calculated to perfection.

- Soldering: Reflow ovens melt solder paste, creating permanent electrical connections. Wave soldering follows, ensuring every joint is secure—a critical step for automotive systems where reliability is non-negotiable.

- Testing and Inspection: Automated Optical Inspection (AOI) and X-ray scanning act as quality guardians, catching defects before they reach consumers. This rigorous testing is especially vital in medical devices, where failure is not an option.

A World Transformed

PCBA technology has infiltrated every corner of our lives:

- Consumer Electronics: Smartphones and tablets owe their sleek designs to compact PCBA solutions.

- Industrial Innovation: Manufacturing machinery relies on robust PCBA to operate seamlessly in harsh environments.

- Medical Breakthroughs: Diagnostic equipment and patient monitoring systems depend on PCBA’s precision and reliability.

- Automotive Advancements: From infotainment systems to autonomous driving modules, PCBA drives the future of transportation.

Challenges and Innovations

Despite its success, PCBA faces challenges. Miniaturization demands push the limits of component placement, while environmental concerns drive the adoption of lead-free soldering. Artificial intelligence (AI) is now stepping into the fray, optimizing design workflows and reducing production errors—a trend poised to redefine efficiency in the coming years.

The Road Ahead

As we stand on the brink of a new era, PCBA continues to evolve. Flexible PCBA for bendable electronics and smart manufacturing techniques are emerging, promising even greater integration into our daily lives. The silent revolution of PCBA, once confined to factory floors, now shapes the very fabric of our digital world.

From its humble beginnings to its current dominance, PCBA remains the unsung hero of the electronics industry—a testament to human ingenuity and the relentless pursuit of progress.