Introduction

Printed Circuit Board Assembly (PCBA) lies at the heart of modern electronics, powering everything from smartphones and medical devices to automotive systems and industrial machinery. As demand for advanced electronics continues to grow, the PCBA Electronic Manufacturing Services (EMS) industry is evolving rapidly, offering both immense opportunities and significant challenges.

The Potential of PCBA EMS

- Expanding Market Demand

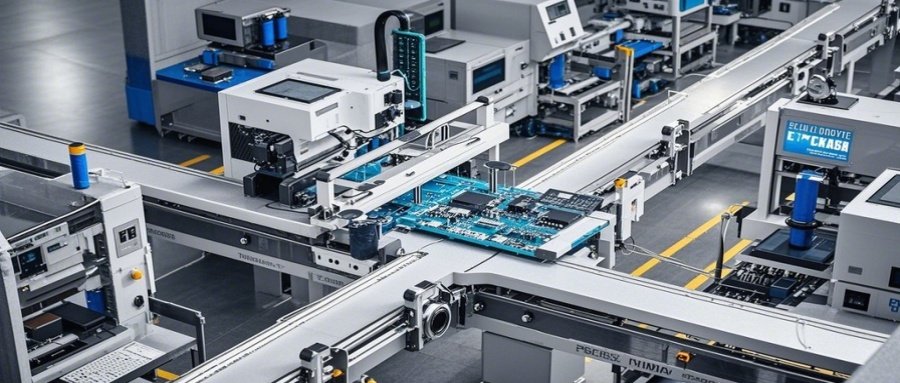

With the rise of IoT, 5G, electric vehicles, and smart devices, the need for high-quality PCBA solutions is increasing exponentially. This creates opportunities for EMS providers to expand their customer base across diverse industries. - Technological Advancements

Automation, AI-driven inspection, and advanced robotics are transforming PCBA production lines. These innovations improve efficiency, reduce defects, and enable mass customization. - Globalization and Outsourcing

Many companies outsource PCBA manufacturing to specialized EMS providers to reduce costs and focus on core competencies. This trend strengthens the role of EMS firms in global supply chains. - Sustainability and Green Manufacturing

Growing awareness of environmental impact is pushing EMS providers to adopt eco-friendly materials, energy-efficient processes, and recycling initiatives, opening new market niches.

Challenges Facing the Industry

- Supply Chain Vulnerabilities

Shortages of semiconductors and critical components can disrupt production schedules, leading to delays and increased costs. - Rising Labor and Operational Costs

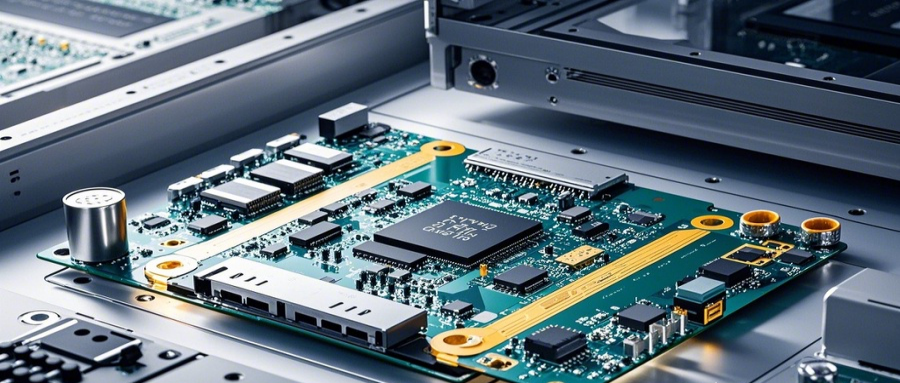

While automation reduces dependency on manual labor, skilled technicians are still essential. Recruiting and retaining talent remains a challenge. - Quality Assurance and Reliability

As electronics become more complex, ensuring flawless PCBA performance is critical. Failures can lead to costly recalls and damage to brand reputation. - Geopolitical and Trade Issues

Tariffs, export restrictions, and regional conflicts can impact the availability of raw materials and affect global EMS operations. - Rapid Technological Change

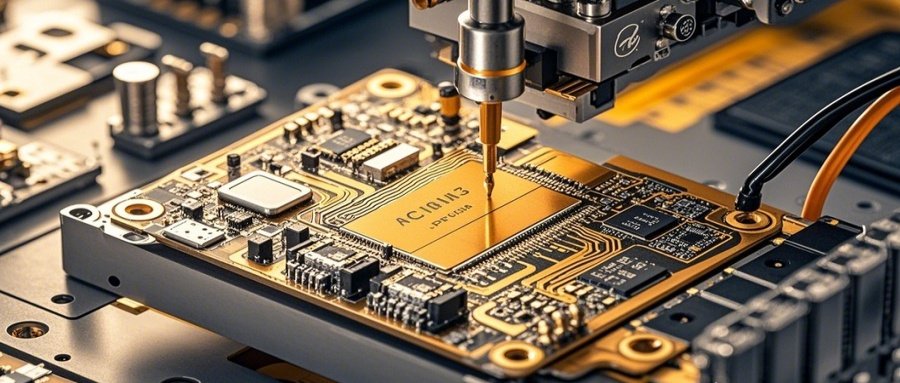

EMS providers must continuously invest in new equipment and training to keep pace with evolving technologies, which can strain financial resources.

Future Outlook

The PCBA EMS industry is poised for strong growth, driven by digital transformation and the proliferation of smart technologies. Companies that embrace automation, sustainability, and agile supply chain strategies will be best positioned to thrive. However, success will depend on balancing innovation with resilience against global uncertainties.

Conclusion

The PCBA Electronic Manufacturing Services industry stands at a crossroads of opportunity and challenge. By leveraging advanced technologies, strengthening supply chains, and prioritizing sustainability, EMS providers can unlock enormous potential while navigating the complexities of a rapidly changing global market.