Precision in the Sub-Millimeter World

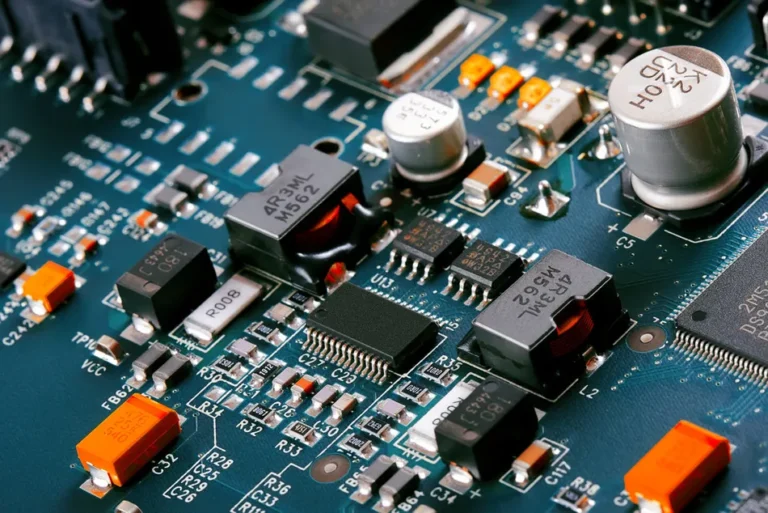

Driven by the demand for smaller, lighter, and more powerful devices (wearables, medical sensors, 5G modules), PCBA manufacturing is rapidly moving towards micro-miniaturization. This trend means adopting tiny, passive components like the 0201 (0.6mm*0.3mm) and the even smaller 01005 (0.4mm*0.2mm).

These components are barely visible to the naked eye. Handling and placing them successfully is the ultimate test of a PCBA supplier’s precision equipment, process control, and engineering expertise. This article details the three critical factors necessary to achieve high-yield Surface Mount Technology (SMT) for ultra-fine-pitch components.

Factor 1: Ultra-Precision Equipment and Placement Control

The physical limits of SMT must be managed with state-of-the-art machinery.

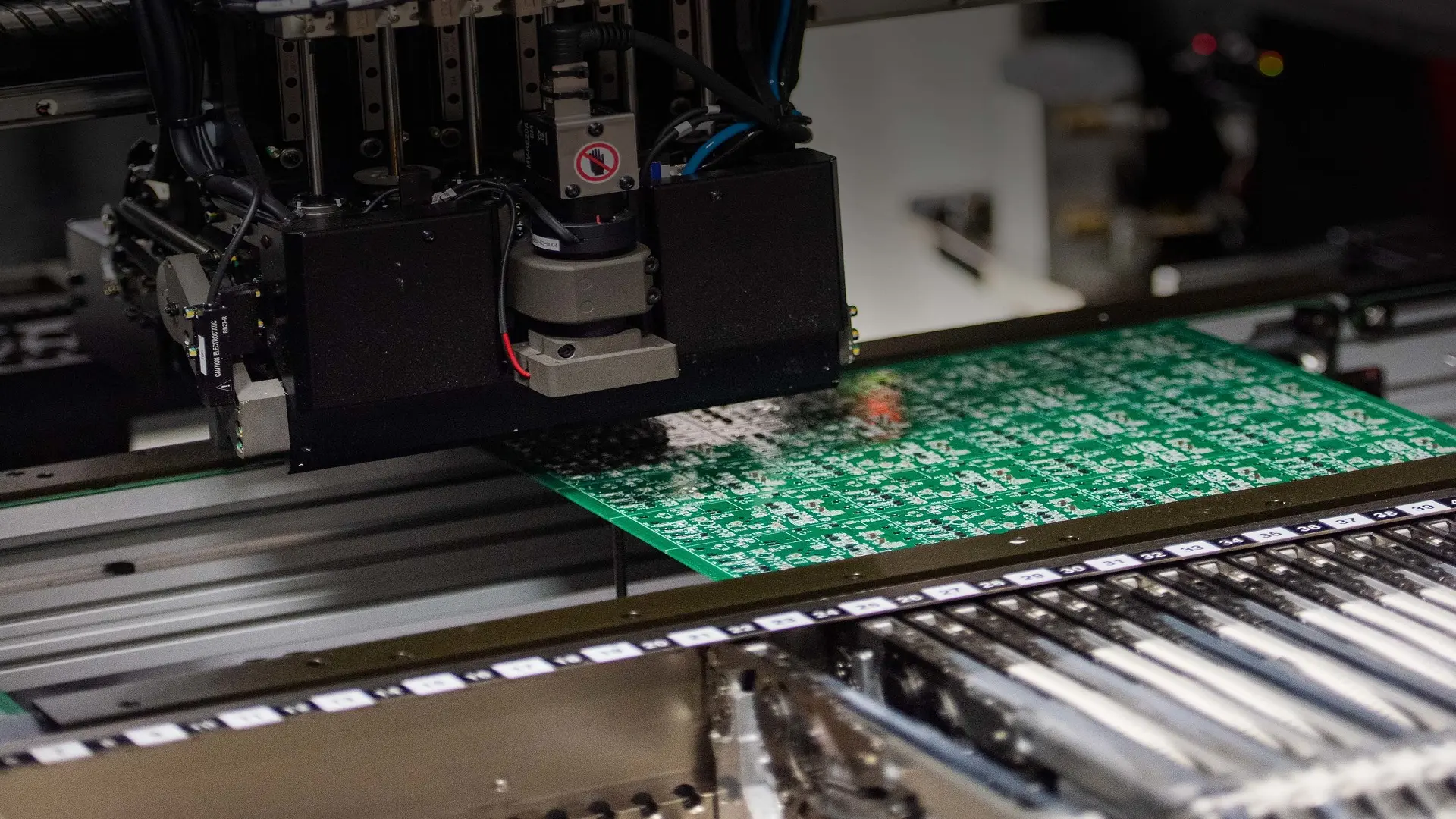

- High-Speed, High-Precision Placement Machines: Successful 01005 assembly requires pick-and-place machines with exceptional repeatability and linear encoders to ensure the component is placed accurately onto the tiny solder pad. These machines must be frequently calibrated to maintain sub-micron tolerances.

- Optimized Nozzle and Feeder Systems: The delicate vacuum nozzles must be specifically designed for the miniature size of 01005 components to prevent damage or mis-picks. Feeder systems must be highly reliable to ensure consistent and correct component presentation.

- Vibration and Environment Control: The SMT line must be isolated from ground vibration, and the clean room environment must be strictly controlled (temperature, humidity) to prevent microscopic particle contamination that could affect placement or soldering.

Factor 2: Stencil Printing and Solder Paste Management

Solder paste deposition is arguably the single most critical step for micro-miniaturization yield.

- Nano-Coated Stencils and Laser Cut Precision: Stencils used for 01005 must be exceptionally thin (often $<100 \mu m$) and manufactured with high-precision laser cutting. Furthermore, a nano-coating on the stencil dramatically improves paste release from the tiny apertures, ensuring consistent solder volume.

- Fine-Grain Solder Paste: Standard solder paste often contains granules too large for 01005 apertures. Type 4 or Type 5 ultra-fine-grain solder paste must be used to ensure the paste prints cleanly and uniformly.

- Automated Solder Paste Inspection (SPI): 3D SPI is mandatory. This technology measures the volume, height, and area of every single solder deposit before component placement. Detecting insufficient or excessive paste volume at this stage prevents the majority of future defects (opens, shorts, tombstoning).

Factor 3: Reflow Profiling and Defect Mitigation

The delicate process of reflow soldering must prevent micro-defects common in small components.

- Precise Reflow Profiling: The reflow profile (heating, soaking, peak, and cooling zones) must be meticulously optimized. A profile that is too steep can cause component tombstoning (where surface tension pulls one end of the component up), while insufficient heat leads to cold joints.

- Nitrogen Atmosphere: Using a Nitrogen (N2) atmosphere in the reflow oven is often required for high-reliability, micro-pitch assemblies. Nitrogen prevents oxidation, improving solder joint wetting and ensuring maximum joint strength and quality.

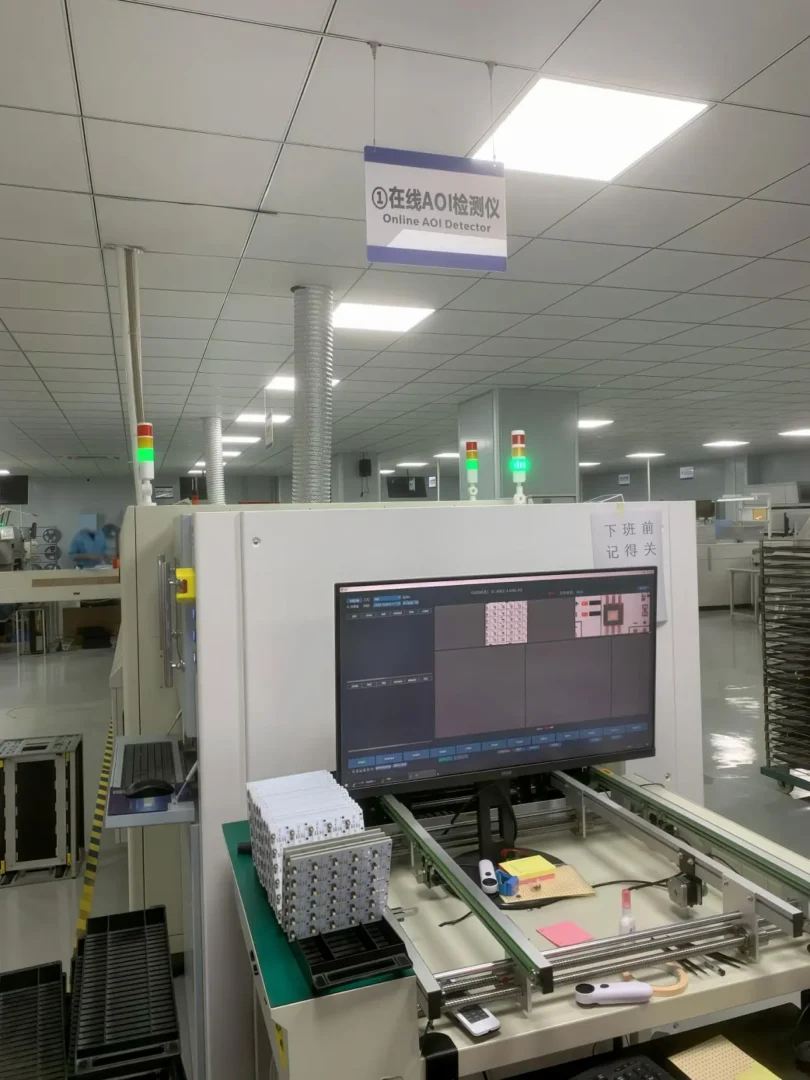

- Advanced Inspection (AOI and X-Ray): After reflow, High-Resolution AOI is essential for detecting misalignment. Automatic X-Ray Inspection (AXI) is mandatory for checking solder joint quality and voids under non-visible packages like BGA and QFN, which often accompany fine-pitch components on high-density boards.

Conclusion and Call to Action

Successfully handling 01005 components is a benchmark of manufacturing excellence. It requires not just investment in premium SMT equipment but also a deep mastery of solder paste chemistry, stencil technology, and process control. This level of precision is non-negotiable for high-density, mission-critical products.

Is your current supplier ready for the micro-miniaturization era? Challenge our SMT experts today to review your design and ensure high-yield assembly for your next generation of miniature products.