When the Price Drops Below Market Average, Alarms Should Ring

In PCBA procurement, a low price is always attractive. However, if a supplier’s quote is significantly below the industry average, you face a dilemma: accepting the low price may bring short-term savings, but the hidden risks of poor quality, unstable supply chains, and long-term reliability issues will ultimately result in a higher Total Cost of Ownership (TCO).

This article will reveal four common “traps” found in low-cost PCBA services and provide three key quality assurance mechanisms for evaluating low-price suppliers, helping you find a secure balance between cost and quality.

Four Common “Traps” in Low-Cost PCBA Services

Low-price competition is often achieved by compromising one or more of the following critical areas:

- Trap 1: Raw Material Downgrade or Substitution:

- Manifestation: The supplier uses cheaper, low-Tg laminate materials (e.g., non-standard FR4) for bare PCB fabrication, or substitutes auxiliary materials like solder paste and flux during mass production.

- Consequences: Compromises the board’s reliability under high load (e.g., delamination, blistering) and reduces soldering integrity, leading to performance degradation, especially in high-frequency applications.

- Trap 2: Component Sourcing Channel Risk (Counterfeit Components):

- Manifestation: To secure a lower price, the supplier bypasses authorized distributors and sources critical chips and memory from the unofficial Open Market or grey channels.

- Consequences: Increases the risk of procuring counterfeit or refurbished components, which can result in extremely low batch yields or catastrophic failures after delivery.

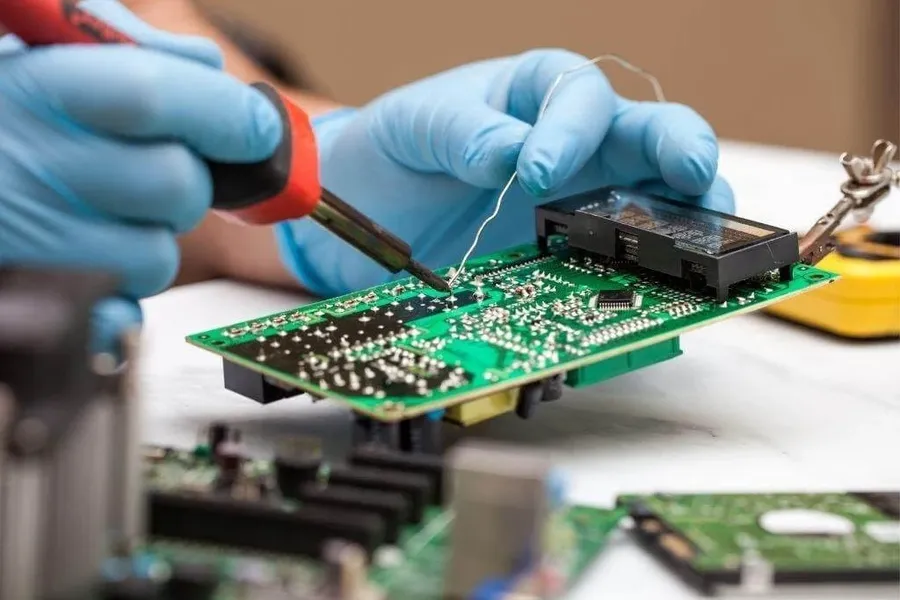

- Trap 3: Simplified or Skipped Testing (Skipping Tests):

- Manifestation: To cut corners and reduce costs, the supplier may reduce or skip necessary tests, such as the coverage of ICT/FCT, X-Ray inspection, and AOI (Automated Optical Inspection).

- Consequences: Defective boards enter the market; the cost of customer recall, warranty claims, and brand reputation damage will far exceed the saved testing fees.

- Trap 4: Sacrifice of Traceability and Documentation:

- Manifestation: Low-cost providers often lack a robust MES (Manufacturing Execution System), failing to provide detailed production data, reflow profiles, and batch traceability records.

- Consequences: In the event of a quality issue, the inability to quickly locate the defective batch, responsible process, and root cause leads to prolonged troubleshooting time.

Three Key Assurance Mechanisms to Balance Price and Quality

You must demand that low-price suppliers possess the following mechanisms to prove their cost advantage stems from efficiency, not quality compromise:

- Assurance 1: Supply Chain Transparency and Locking Mechanism (BOM Lock & Transparency):

- Requirement: The supplier must commit that all components originate from authorized Tier 1 channels and implement a BOM Lock for critical components. Furthermore, they should provide component sourcing traceability documentation.

- Assessment Point: Inquire about their counterfeit verification process (e.g., X-Ray or solderability testing).

- Assurance 2: Standardized Quality Management System (QMS):

- Requirement: The supplier must hold certifications like ISO 9001, and their production process must support First Article Inspection (FAI) and Statistical Process Control (SPC).

- Assessment Point: Pay close attention to their DFM/DFA report; if they have the capability to detect and eliminate flaws at the design stage, rework costs naturally decrease, and the quote is more reasonable.

- Assurance 3: In-House Manufacturing and Process Control:

- Requirement: Choose a supplier with an in-house factory over a pure trader. An in-house factory can achieve genuine cost reduction through equipment automation and process optimization (e.g., lean manufacturing).

- Assessment Point: True low cost should be derived from economies of scale and high efficiency, not rudimentary equipment and outsourced processes.

Conclusion and Call to Action

Low-cost PCBA is only valuable when the quality is stable, traceable, and the supply chain is reliable. Your goal should not be the lowest price, but the lowest Total Cost of Ownership (TCO). A mature PCBA partner will provide a transparent cost structure and prove that their price advantage stems from superior operational efficiency and risk control.

Don’t let short-term savings compromise your long-term brand value. Contact our experts to learn how we provide competitive, high-quality PCBA services through efficiency and a controlled supply chain!