Abstract

Surface Mount Technology (SMT) has become the predominant methodology in electronic assembly due to its efficiency, miniaturization capability, and compatibility with automated production. This paper provides a concise yet academically oriented overview of the principal stages in the SMT process flow, highlighting the technical rationale and quality assurance mechanisms inherent to each step.

1. Introduction

The evolution of electronic packaging has shifted from through-hole technology to SMT, enabling higher component density and improved electrical performance. SMT relies on the direct placement of surface-mount devices (SMDs) onto printed circuit boards (PCBs), thereby reducing assembly time and enhancing reliability. Understanding the sequential process flow is essential for both manufacturing optimization and defect prevention.

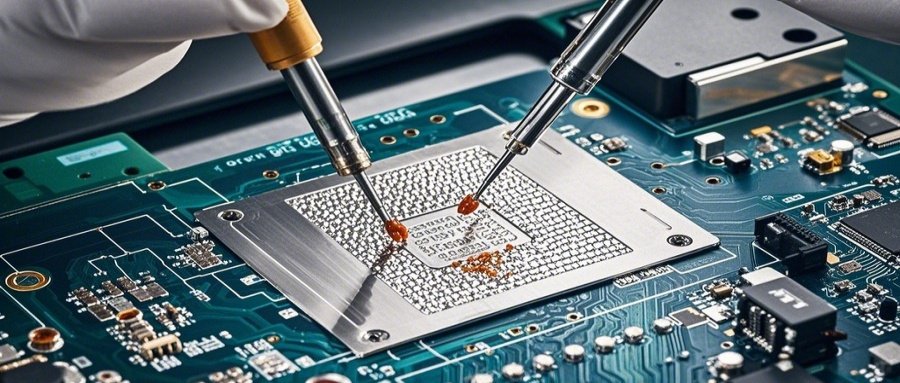

2. Solder Paste Deposition

The initial stage involves the application of solder paste onto designated PCB pads using a stainless-steel stencil. The rheological properties of solder paste, comprising metallic solder particles suspended in flux, are critical to ensuring uniform deposition. Accurate paste printing directly influences subsequent component placement and solder joint integrity.

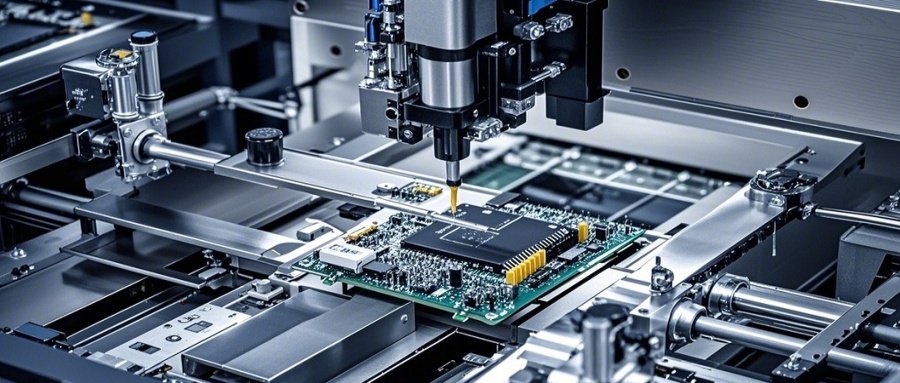

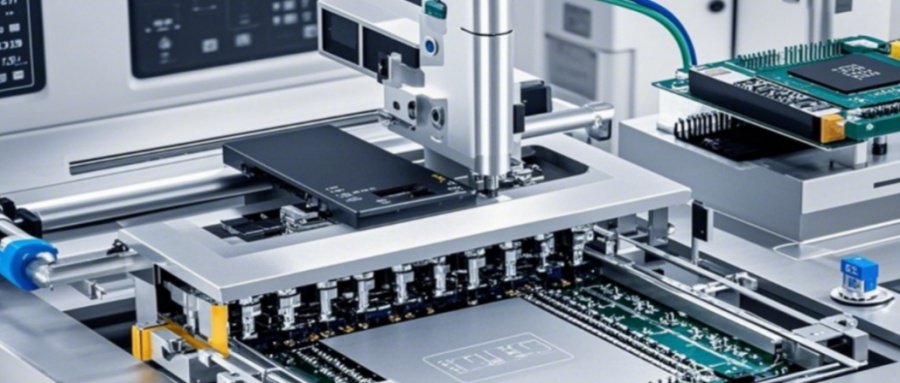

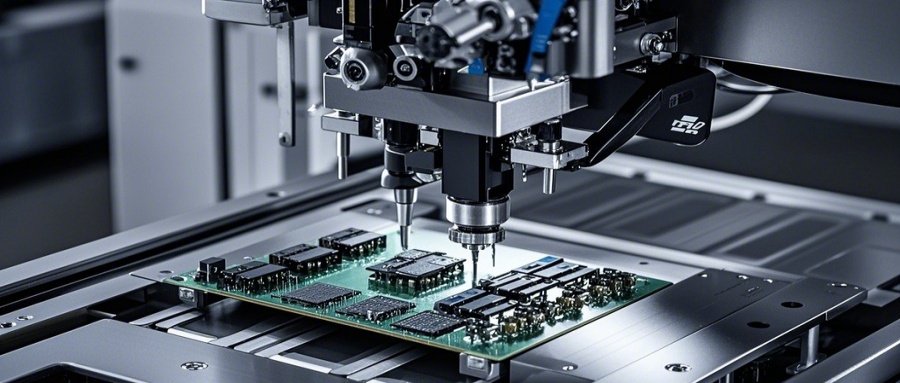

3. Component Placement

Automated pick-and-place systems position SMDs onto the solder-pasted pads with high precision. Placement accuracy is governed by machine vision systems and alignment algorithms. Misplacement at this stage can lead to electrical discontinuities or mechanical instability, underscoring the importance of robust equipment calibration.

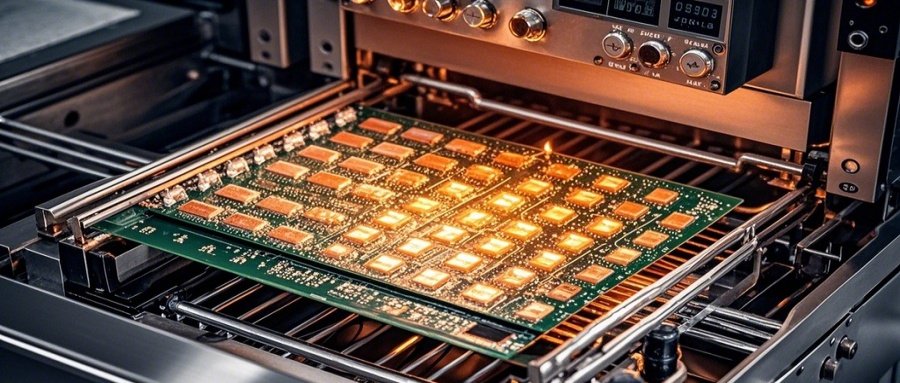

4. Reflow Soldering

The reflow process subjects the PCB to a controlled thermal profile within a reflow oven. Distinct heating zones—preheat, soak, reflow, and cooling—facilitate flux activation, solder melting, and eventual solidification. The resulting metallurgical bonds ensure both electrical conductivity and mechanical strength. Thermal management is crucial to avoid defects such as tombstoning, voids, or cold joints.

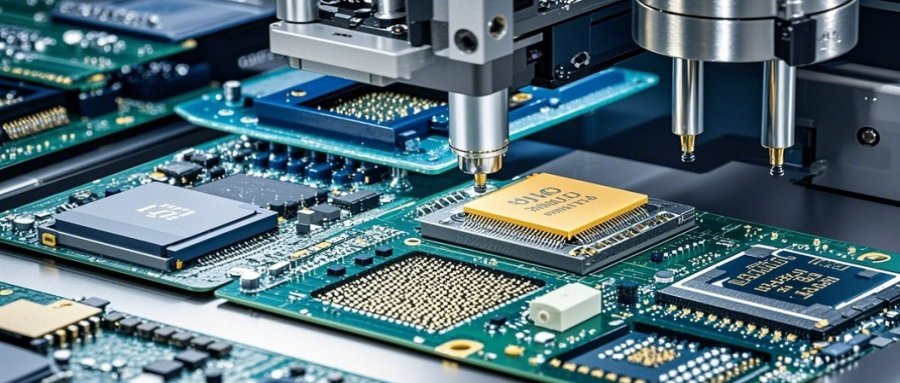

5. Inspection and Quality Assurance

Post-reflow inspection employs Automated Optical Inspection (AOI) and, for hidden joints such as Ball Grid Arrays (BGAs), X-ray analysis. These non-destructive techniques detect anomalies including solder bridging, insufficient wetting, or component misalignment. Statistical Process Control (SPC) is often integrated to monitor defect trends and maintain process stability.

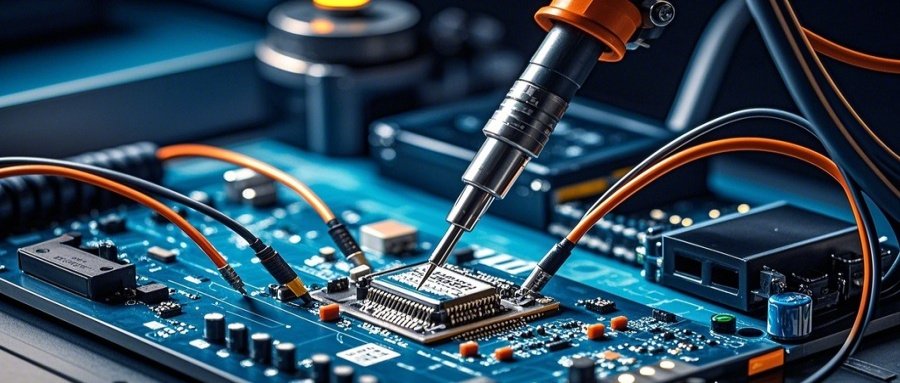

6. Electrical Testing

Functional validation is achieved through In-Circuit Testing (ICT) and system-level tests. These procedures verify circuit continuity, signal integrity, and compliance with design specifications. Testing serves as the final safeguard against latent defects that could compromise product reliability.

7. Conclusion

The SMT process flow—comprising solder paste deposition, component placement, reflow soldering, inspection, and testing—represents a highly integrated manufacturing paradigm. Each stage is interdependent, and deviations in one can propagate defects downstream. A rigorous understanding of this flow is indispensable for advancing electronic manufacturing practices and ensuring product quality.