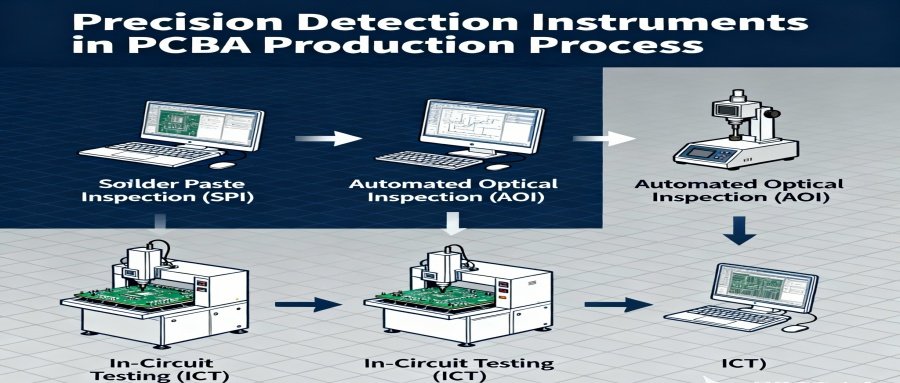

Precision Detection Instruments in the PCBA Production Process

Printed Circuit Board Assembly (PCBA) is a highly complex and controlled manufacturing process. Each stage of production is governed by dedicated software programs, and for every program, there is a corresponding detection instrument to ensure compliance with technical specifications, process stability, and product reliability.

1. Solder Paste Printing

- Program Function: Controls stencil printing parameters such as pressure, speed, and alignment.

- Detection Instrument: Solder Paste Inspection (SPI) systems measure paste volume, height, and position accuracy.

- Technical Value: SPI provides 3D measurement data, enabling closed-loop feedback to adjust printing parameters in real time.

2. Component Placement

- Program Function: Pick-and-place machines execute placement coordinates and rotation angles.

- Detection Instrument: Automated Optical Inspection (AOI) validates component presence, polarity, and solder pad alignment.

- Technical Value: AOI uses high-resolution cameras and image-processing algorithms to detect misplacements down to micrometer precision.

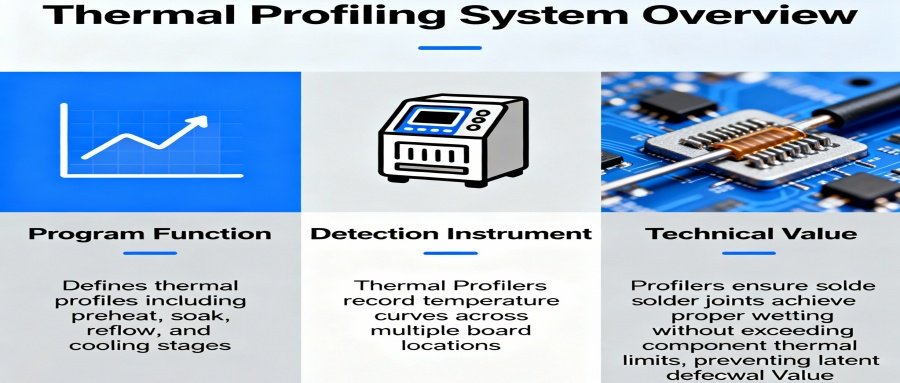

3. Reflow Soldering

- Program Function: Defines thermal profiles including preheat, soak, reflow, and cooling stages.

- Detection Instrument: Thermal Profilers record temperature curves across multiple board locations.

- Technical Value: Profilers ensure solder joints achieve proper wetting without exceeding component thermal limits, preventing latent defects.

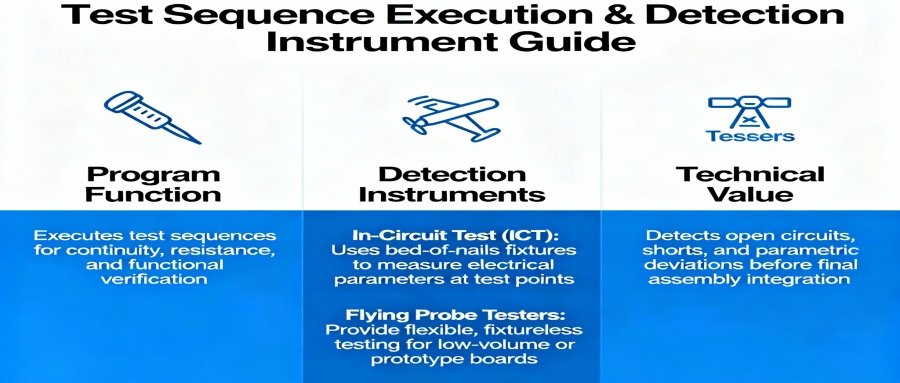

4. Electrical Testing

- Program Function: Executes test sequences for continuity, resistance, and functional verification.

- Detection Instruments:

- In-Circuit Test (ICT): Uses bed-of-nails fixtures to measure electrical parameters at test points.

- Flying Probe Testers: Provide flexible, fixtureless testing for low-volume or prototype boards.

- Technical Value: Detects open circuits, shorts, and parametric deviations before final assembly integration.

5. Final Functional Verification

- Program Function: Runs firmware or simulation routines to validate board-level performance.

- Detection Instrument: Functional Test Systems simulate real-world operating conditions.

- Technical Value: Confirms that the PCBA meets customer specifications under load, signal, and environmental stress conditions.

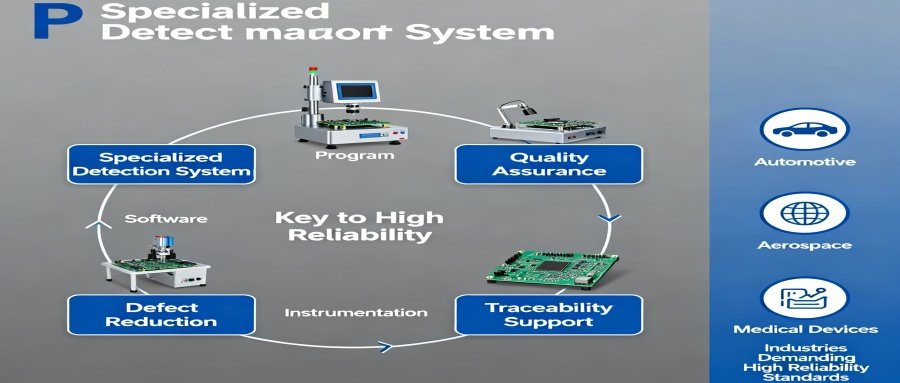

Conclusion

In PCBA manufacturing, detection instruments are not optional add-ons — they are integral to process control. Each program is paired with a specialized detection system, forming a closed-loop mechanism that ensures quality, reduces defects, and supports traceability. This synergy between software and instrumentation is what enables modern electronics to achieve high reliability standards demanded by industries such as automotive, aerospace, and medical devices.