In the realm of electronics manufacturing, Printed Circuit Board Assembly (PCBA) stands as a cornerstone technology, enabling the functionality of countless devices we use daily. This article delves into the intricacies of PCBA, its significance, and how it powers the digital world.

Understanding PCBA

PCBA is the process of assembling electronic components onto a printed circuit board (PCB). Unlike PCB, which refers to the bare board, PCBA involves populating the board with components like resistors, capacitors, and integrated circuits to create a functional electronic system. This process is critical in industries ranging from consumer electronics to automotive and aerospace.

The PCBA Process

The assembly process typically involves three key stages:

- Component Placement: High-precision machines accurately place components onto the PCB. Modern surface-mount technology (SMT) allows for components as small as a grain of rice to be placed with micron-level accuracy.

- Soldering: Components are permanently attached to the board through soldering, often using reflow ovens or wave soldering techniques. This creates reliable electrical connections between components and the board’s circuitry.

- Testing and Inspection: Rigorous quality control measures, including automated optical inspection (AOI) and X-ray testing, ensure each assembled board meets stringent standards before deployment.

Applications Across Industries

PCBA technology is ubiquitous in modern electronics:

- Consumer Electronics: Smartphones, tablets, and wearable devices rely on compact PCBA designs

- Industrial Equipment: Manufacturing machinery and automation systems depend on robust PCBA solutions

- Medical Devices: From diagnostic equipment to patient monitoring systems, PCBA enables precision and reliability

- Automotive: Advanced driver-assistance systems (ADAS) and infotainment systems are powered by PCBA technology

Why PCBA Matters

The importance of PCBA lies in its ability to:

- Enable miniaturization of electronic devices

- Improve reliability and performance of electronic systems

- Facilitate mass production of complex electronic assemblies

- Support innovation in emerging technologies like IoT and AI

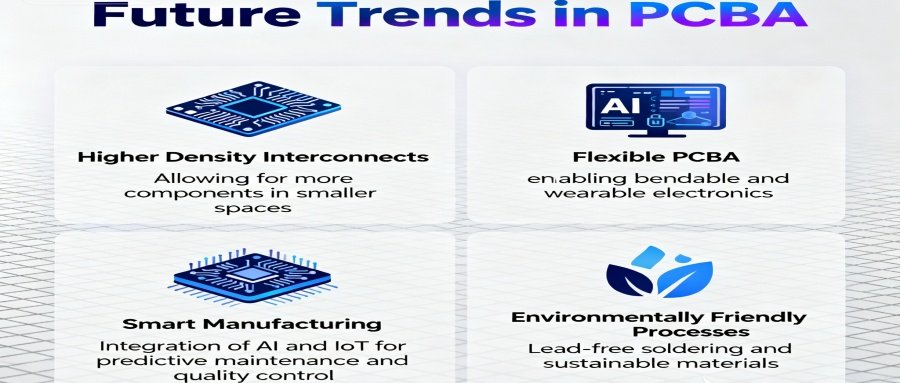

Future Trends in PCBA

As technology evolves, PCBA processes are advancing with:

- Higher Density Interconnects: Allowing for more components in smaller spaces

- Flexible PCBA: enabling bendable and wearable electronics

- Smart Manufacturing: Integration of AI and IoT for predictive maintenance and quality control

- Environmentally Friendly Processes: Lead-free soldering and sustainable materials

PCBA technology continues to evolve, driving innovation across all sectors of electronics. As devices become more sophisticated and interconnected, the demand for advanced PCBA solutions will only grow, reinforcing its position as a fundamental technology in the digital age.