Printed Circuit Board Assembly (PCBA) is the backbone of modern electronics manufacturing. For factories, yield—the percentage of defect-free boards produced—is a critical measure of efficiency, cost control, and customer satisfaction. Improving yield requires a combination of technical precision, process optimization, and quality management. Below are the key strategies that can significantly enhance PCBA yield in a factory environment.

1. Rigorous Component Quality Control

- Supplier management: Partner with reliable suppliers who provide consistent, high-quality components.

- Incoming inspection: Implement strict checks for moisture sensitivity, counterfeit risks, and dimensional accuracy.

- Storage conditions: Maintain proper humidity and temperature to prevent oxidation or degradation.

2. Optimized Soldering Processes

- Reflow profiling: Develop precise thermal profiles to ensure proper solder joint formation.

- Wave soldering control: Monitor flux application, preheat zones, and solder pot cleanliness.

- Material selection: Use solder paste with stable viscosity and low voiding characteristics.

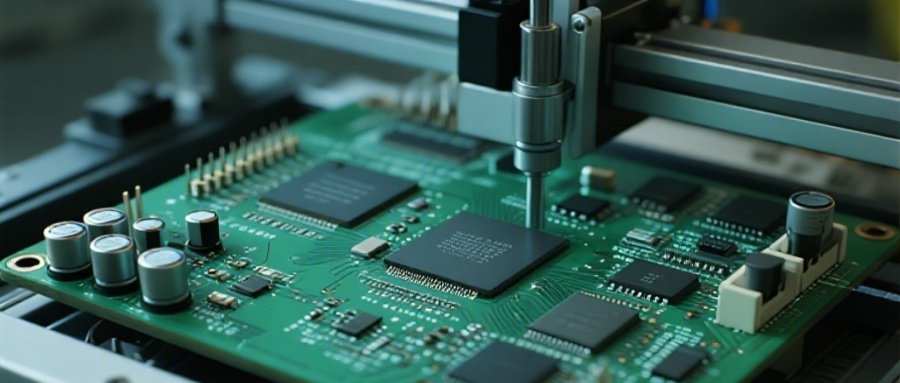

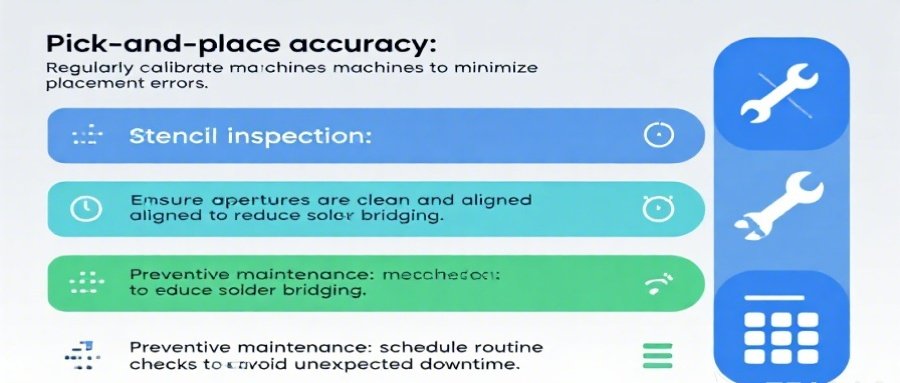

3. Advanced Equipment Calibration and Maintenance

- Pick-and-place accuracy: Regularly calibrate machines to minimize placement errors.

- Stencil inspection: Ensure apertures are clean and aligned to reduce solder bridging.

- Preventive maintenance: Schedule routine checks to avoid unexpected downtime.

4. Robust Process Monitoring and Data Analytics

- Automated Optical Inspection (AOI): Detect misalignments, solder defects, and missing components early.

- Statistical Process Control (SPC): Track yield trends and identify root causes of variation.

- Real-time dashboards: Provide operators with actionable insights to correct issues quickly.

5. Skilled Workforce and Continuous Training

- Operator certification: Train staff on IPC standards and best practices.

- Cross-functional teams: Encourage collaboration between engineering, quality, and production.

- Continuous improvement culture: Promote Kaizen initiatives to refine processes.

6. Environmental and ESD Control

- Electrostatic discharge (ESD) protection: Use wrist straps, mats, and ionizers to safeguard sensitive components.

- Cleanroom practices: Reduce contamination from dust and particles.

- Climate control: Maintain stable temperature and humidity to prevent soldering defects.

Conclusion

Improving PCBA yield is not a single-step solution but a holistic approach that integrates component quality, process optimization, equipment reliability, data-driven monitoring, and human expertise. Factories that invest in these strategies not only reduce costs and waste but also strengthen their reputation for delivering reliable, high-performance electronic products.