What is PCB Conformal Coating?

Why PCB Conformal Coating Is Essential for Reliability

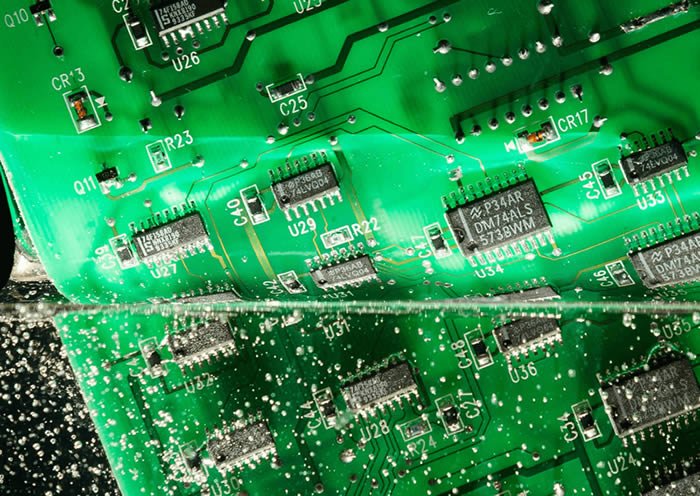

The performance of PCB can deteriorate due to various factors, including the operating environment. Thus, to make your PCB perform well and make it long-lasting, you need to protect it. Conformal Coating acts like a protective layer that protects your circuit board from harsh environmental conditions in the long term. It can withstand environmental conditions like moisture, extreme temperatures, and chemical and salt sprays. These conditions could result in the electric failure of your board. Thus, the coatings ensure the reliability of printed circuit boards, reducing prematurely failed hardware costs. Furthermore, the coating is used to:

- Increase the dielectric between the conductors.

- Provide closer conductor spacing.

- Protects board from corrosion and chemical attacks

- Sometimes, it protects from mechanical stress, too

Types of Conformal Coatings

There are various types of conformal coating available on the market. Each one has its characteristics. Let’s look into some of the widely used conformal coating in the PCB industry:

Acrylic Resin (AR) Coating

Acrylic conformal coatings are commonly used due to their excellent dielectric strength. They provide a fair level of protection against moisture and abrasion and are particularly noted for their ease of removal. This feature makes them ideal for applications requiring rework or repair.

Pros

- High dielectric strength

- easy to remove for rework or repair

- Cost-effective

- provides essential protection against a range of contaminants.

Cons

- Not resistant to solvents

- less durable compared to other types

- not suitable for high-stress environments.

Silicone Resin (SR) Coatings

Silicone coatingsare known for their flexibility and excellent performance across a wide temperature range. They offer good resistance to chemicals, moisture, and salt spray, making them suitable for high-humidity environments.

Pros

- Great for extreme temperatures

- Flexible

- good chemical and moisture resistance

- ideal for high-humidity conditions.

Cons

- Not abrasion-resistant

- difficult to remove

- can be challenging to apply evenly.

Urethane Resin (UR) Conformal Coating

Urethane coatingsare known for their moisture and chemical resistance. They are also abrasion-resistant. Thus, it makes them a robust choice for demanding applications.

Pros

- Excellent moisture and chemical resistance

- high abrasion resistance

- suitable for harsh environments like aerospace applications.

Cons

- Very difficult to remove

- limited reworkability

- can be sensitive to UV light

Epoxy Conformal Coatings

Epoxy coatingsare known for their hardness and excellent humidity resistance. These two-part compounds create a very durable and non-permeable layer.

Pros

- Strong humidity resistance

- high abrasion

- chemical resistance

- very durable once cured

Cons

- Difficult to remove

- not flexible

- hard apply

Parylene Conformal Coating

Parylene coatings are unique in their application method (vapor phase deposition). It provides exceptional dielectric strength. They offer unparalleled resistance to moisture, solvents, and extreme temperatures.

Pros

- superior moisture and solvent resistance

- excellent dielectric strength

- thin yet effective coverage

Cons

- difficult to remove for rework

- requires specialized equipment for application

- expensive

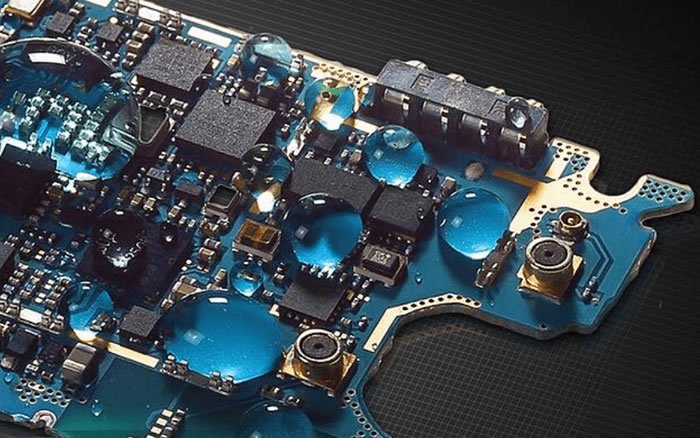

Thin Film/Nano Coatings

It is applied in a very thin layer. It provides a basic level of hydrophobicity. It protects against quick water exposure.

Pros

- suitable for light moisture exposure

- can be applied thinly and uniformly

Cons

- Limited protection compared to other types

- not suitable for harsh environments

- provides minimal surface protection

Step-by-Step: How to Apply PCB Conformal Coating

Conformal Coating can be applied in the following ways:

- Prepare the Surface: First, clean the electronic board to remove any dust or other particles. This ensures the coating adheres well.

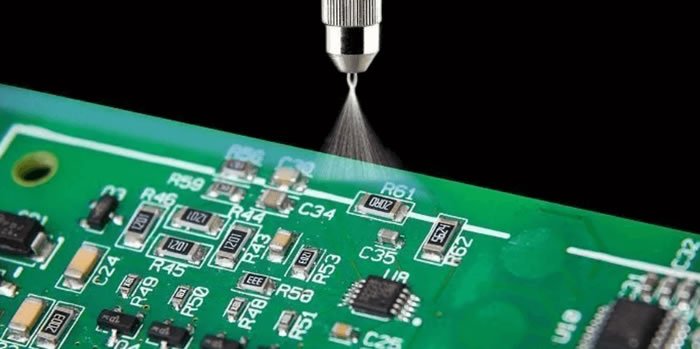

- Apply the Coating: There are various methods to apply conformal coating. It includes dipping, brushing, and spraying. Spraying is used for large batches, bruising for small areas, and dipping for equal and uniform coverage.

- Curing the Coating: After applying the coating, it should be set. This can be done naturally or with heat or UV light, depending on the type of Coating used.

- Inspection: Finally, inspect the board to ensure the Coating is applied uniformly. Ensure there are no missed spots or bubbles.

PCB Conformal Coating Process

Conformal Coating is a critical method for shielding circuit boards and electronic components from harsh weather conditions. Here is a brief guide to the many ways to apply conformal coating.

Manual Spraying

This method involves using an aerosol can or handheld spray gun. It’s typically used for low-volume production when more sophisticated equipment isn’t available.

- Pros: Good for small batches and specific areas.

- Cons: It is time-consuming and requires manual masking of areas not to be coated. Quality may vary due to operator dependency.

Selective Coating

In this automated process, programmable robotic spray nozzles apply the coating to precise areas on the circuit board. It is ideal forhigh-volumeproduction and eliminates the need for masking. It requires advanced equipment and programming.

Dipping

The PCB is immersed in the conformal coating material. The immersion and withdrawal speed, as well as the viscosity of the coating, determine the film formation. It helps to apply the coating uniformly. It is suitable for high-volumeprocessing. At the same time, the process required extensive masking.

Brushing

It is a simple technique where the brush is used to apply the coating in specific areas, mainly used in repair and rework applications. It is low-cost and straightforward for small areas or repairs. At the same time, it is labour-intensive and highly variable, not suitable for large-scale applications.

Dilution

High-viscosity coatings may be diluted with solvents like acetone or toluene for more straightforward application. It allows for consistent coating thickness and ease of application. It requires careful handling and precise mixing to maintain coating properties.

Cure Methods

Silicone conformal coatings typically cure with exposure to moisture, reacting with ambient moisture to form the polymer coating. This can be accelerated with heat. The process is effective, with simultaneous drying and curing. It requires careful control of environmental conditions to prevent issues like blistering.

Key PCB Conformal Coating Standards

Conformal coatings are also applied following specific industry standardscovering PCB acceptance requirements, acceptability of electronic assemblies, and qualification and performance specifications for rigid PCBs. ELEPCB‘s conformal coatings comply with the following standards.

- MIL-I-46058C: This military standard has been around for a long time and is still widely referenced. It sets rigorous testing criteria for conformal coatings used in military applications. Although it’s been inactive for new designs since 1998, many in the industry still adhere to it.

- IPC-CC-830B: This specification is related to MIL-I-46058C but is continually updated. It’s an active specification widely used in the electronics industry.

- UL94V0 and UL746E: Underwriters Laboratories (UL) standards assess conformal coatings for flammability (UL94) and electrical safety (UL746E). They ensure that coatings used on electronics are safe and meet high safety standards.

- IEC 61086: This international standard is similar to MIL-I-46058C but is based on supplier self-certification. It provides a global standard for conformal coatings.

Final Thoughts: Why ELEPCB Is Your Trusted PCB Conformal Coating Partner

If you want to protect your PCB from tough conditions, like moisture and extreme temperatures, think about using a conformal coating. It’s a layer that shields against contaminants, improves electrical properties, and enhances reliability.

Our company, ELEPCB,is an expert in applying coatings like Acrylic, Silicone, Urethane, Epoxy, Parylene, and Thin Film. We adhere to industry standards like MIL-I-46058C and IPC-CC-830B for top-quality work.

We apply coatings using methods like spraying, dipping, and brushing, customized to your needs. Contact usto provide skilled conformal coating, ensuring your electronic components last longer and perform reliably.