What is PCBA?

Printed Circuit Board Assembly (PCBA) refers to the process of mounting and soldering electronic components onto a bare Printed Circuit Board (PCB). While a PCB is simply the board with copper traces, a PCBA is the fully assembled board that can perform specific electronic functions.

Key Steps in PCBA Process

- Design & Layout Engineers design the PCB layout using CAD software, defining where components will be placed and how they will connect.

- Component Procurement Electronic parts such as resistors, capacitors, ICs, and connectors are sourced according to the Bill of Materials (BOM).

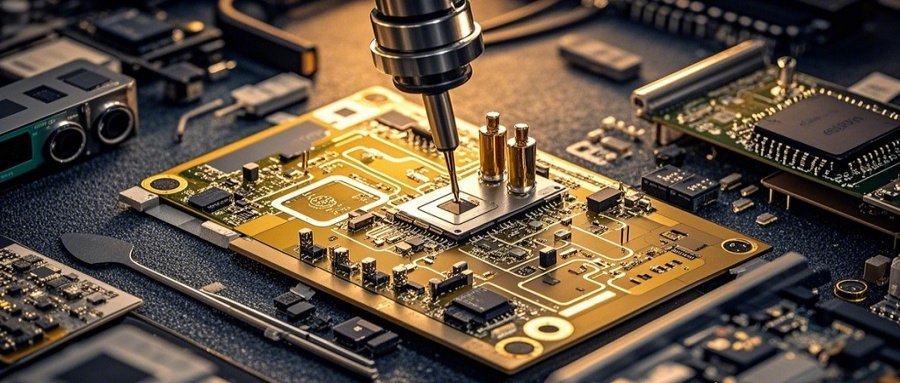

- Solder Paste Printing A stencil is used to apply solder paste onto the PCB pads where components will be mounted.

- Pick and Place Automated machines place surface-mount devices (SMDs) onto the board with high precision.

- Reflow Soldering The board passes through a reflow oven, melting the solder paste to permanently attach components.

- Through-Hole Assembly Larger components may be inserted manually or by machine into drilled holes and soldered, often using wave soldering.

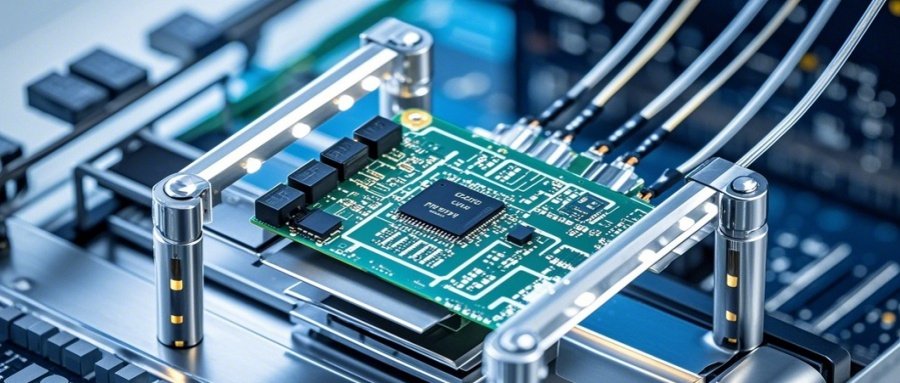

- Inspection & Testing Quality checks such as Automated Optical Inspection (AOI), X-ray inspection, and functional testing ensure reliability.

Types of PCBA

- Surface-Mount Technology (SMT): Components are mounted directly onto the PCB surface.

- Through-Hole Technology (THT): Leads of components are inserted into drilled holes and soldered.

- Mixed Technology: Combines SMT and THT for complex boards.

Importance of PCBA

- Miniaturization: Enables compact designs for modern electronics.

- Reliability: Ensures stable electrical connections and long product life.

- Scalability: Supports mass production with automated assembly lines.

- Functionality: Transforms a passive PCB into an active electronic circuit.

Applications

PCBA is the backbone of nearly all electronic devices, including:

- Smartphones and computers

- Automotive electronics

- Medical devices

- Industrial control systems

- Consumer electronics (TVs, wearables, home appliances)

In short, PCBA is the critical step that brings a PCB to life, turning a simple board into a functional electronic system.