Introduction

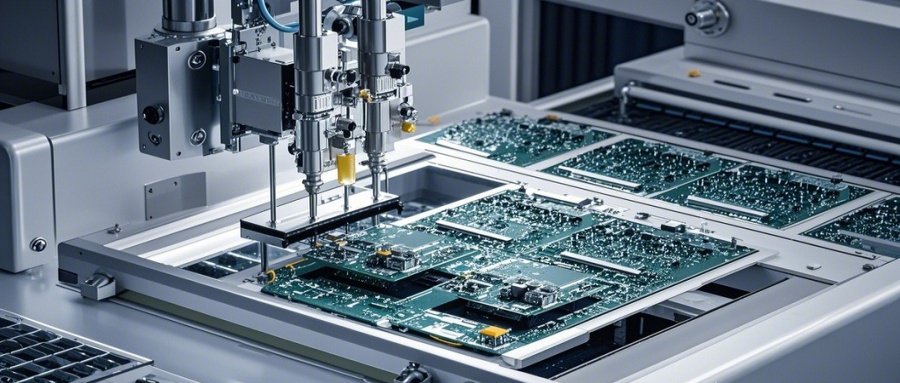

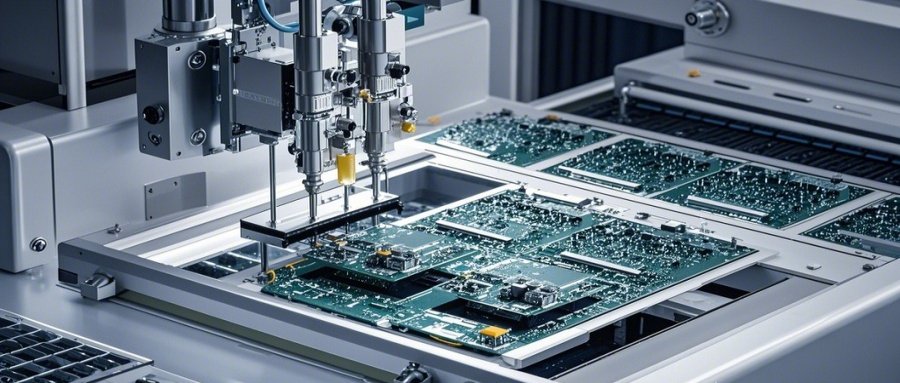

Printed Circuit Board Assembly (PCBA) is the backbone of modern electronic devices, ensuring that components are correctly mounted and interconnected. As electronic products become increasingly complex, testing methods must evolve to guarantee reliability and performance. One such advanced method is Flying Probe Testing (FPT), a versatile and cost-effective solution for verifying PCBAs.

What is Flying Probe Testing?

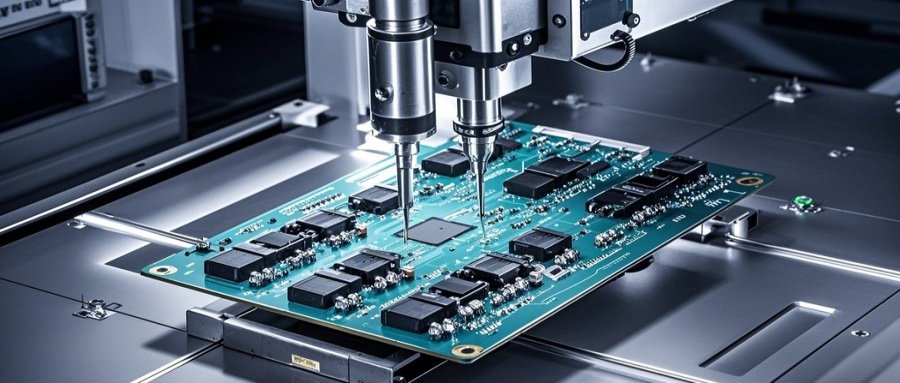

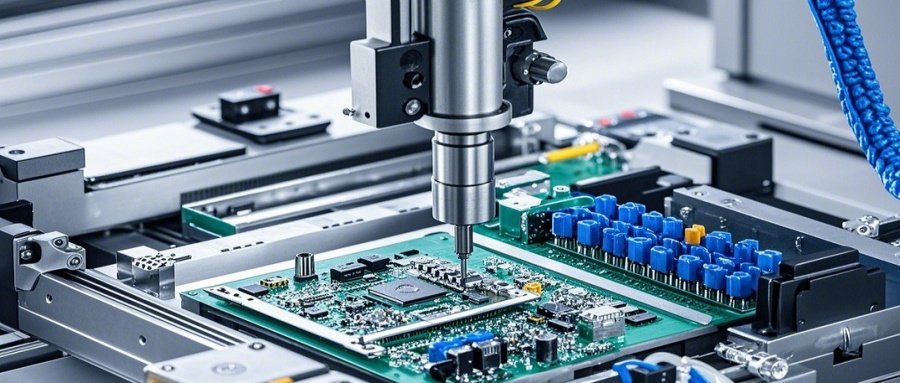

Flying Probe Testing is an automated electrical test method that uses movable probes to contact test points on a PCB. Unlike traditional bed-of-nails fixtures, flying probes do not require a custom fixture, making them ideal for prototypes, small production runs, and boards with high design variability.

Key Features:

- Flexibility: Probes can move freely to access test points across the board.

- No Fixture Requirement: Eliminates the need for expensive and time-consuming test fixtures.

- High Accuracy: Capable of measuring resistance, capacitance, inductance, and detecting shorts or opens.

- Adaptability: Suitable for both bare boards and assembled PCBAs.

Advantages of Flying Probe Testing

- Cost Efficiency: Especially beneficial for low-volume production and prototypes, as fixture costs are avoided.

- Rapid Setup: Test programs can be generated directly from CAD data, reducing preparation time.

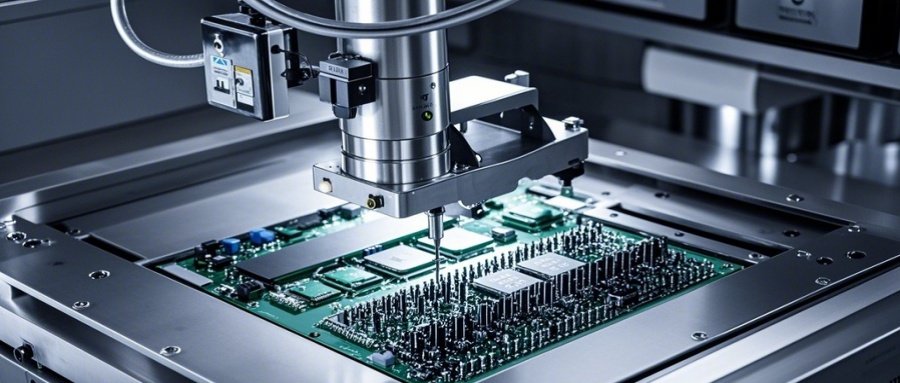

- Comprehensive Coverage: Detects manufacturing defects such as solder bridges, missing components, reversed polarity, and open circuits.

- Non-Destructive: Gentle probing minimizes mechanical stress on delicate assemblies.

Limitations

While flying probe testing offers many benefits, it also has some limitations:

- Slower Throughput: Compared to bed-of-nails testing, flying probes are slower for high-volume production.

- Accessibility Constraints: Some test points may be difficult to reach depending on board layout.

- Limited Parallel Testing: Probes typically test one point at a time, reducing speed.

Applications

Flying Probe Testing is widely used in:

- Prototype Validation: Ensuring design integrity before mass production.

- Low-Volume Manufacturing: Cost-effective testing for specialized or custom boards.

- Complex PCBAs: Boards with dense layouts or fine-pitch components where fixture design is impractical.

Conclusion

Flying Probe Testing has become a cornerstone in modern PCBA quality assurance. Its flexibility, accuracy, and cost-effectiveness make it indispensable for prototypes and specialized production runs. While not always the fastest option for mass production, it provides unmatched adaptability and precision, ensuring that electronic assemblies meet the highest standards of reliability.