Manual soldering remains a fundamental skill in electronics manufacturing and repair, even in an era dominated by automated assembly. Achieving reliable solder joints requires not only technical proficiency but also attention to subtle details that directly impact product quality and longevity. Below are the key aspects every technician must master.

1. Preparation Before Soldering

- Cleanliness of PCB and Components: Dust, oxidation, or oil residues can prevent proper wetting of solder. Always clean pads and leads with isopropyl alcohol before soldering.

- Correct Tools: Use a temperature-controlled soldering iron with an appropriate tip size for the pad and component.

- Material Selection: Choose the right solder alloy (commonly Sn63/Pb37 or lead-free SAC305) and flux type depending on the application.

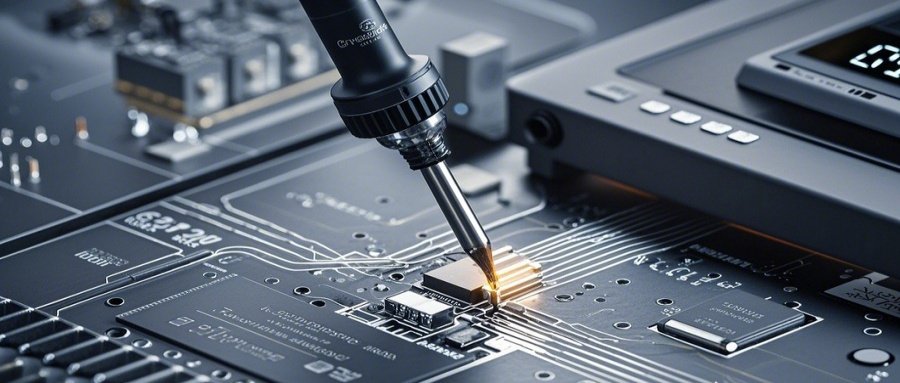

2. Temperature Control

- Optimal Range: Maintain soldering iron temperature between 320–370°C for leaded solder, and slightly higher for lead-free alloys.

- Avoid Overheating: Excessive heat can damage components, lift pads, or cause cold joints if the flux burns off too quickly.

- Preheating Large Pads: For ground planes or heat sinks, preheat the area to ensure proper solder flow.

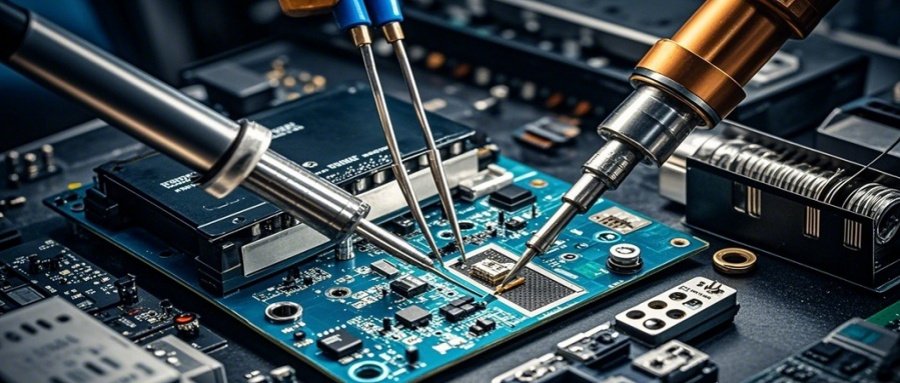

3. Soldering Technique

- Tip Contact: Place the iron tip so it touches both the pad and the component lead simultaneously.

- Solder Feeding: Apply solder to the joint, not directly to the iron tip, ensuring proper wetting.

- Joint Shape: Aim for a smooth, shiny, concave fillet that covers the pad and lead without excess solder.

- Time Control: Each joint should be completed within 2–3 seconds to avoid thermal stress.

4. Flux Usage

- Role of Flux: Removes oxides, improves wetting, and prevents bridging.

- Application: Use flux pens or paste sparingly; excessive flux can leave residues that require cleaning.

- Post-Solder Cleaning: For no-clean flux, cleaning may be optional, but for rosin-based flux, residues should be removed to prevent corrosion.

5. Safety and Reliability Considerations

- ESD Protection: Always wear an anti-static wrist strap when handling sensitive components.

- Ventilation: Ensure proper fume extraction to avoid inhaling flux vapors.

- Inspection: Use magnification tools to check for cold joints, solder bridges, or insufficient wetting.

- Mechanical Strength: Verify that components are firmly seated and solder joints can withstand mechanical stress.

6. Common Defects to Avoid

- Cold Joints: Dull, grainy appearance caused by insufficient heat or poor wetting.

- Bridging: Excess solder creating unintended connections between adjacent pads.

- Lifted Pads: Overheating or excessive force can detach copper pads from the PCB.

- Excessive Solder: Bulky joints may hide defects and cause shorts.

Conclusion

Mastering manual PCBA soldering requires precision, patience, and strict adherence to best practices. By focusing on preparation, temperature control, technique, flux management, and inspection, technicians can ensure reliable and durable solder joints. These details not only improve product quality but also reduce rework and enhance long-term performance.