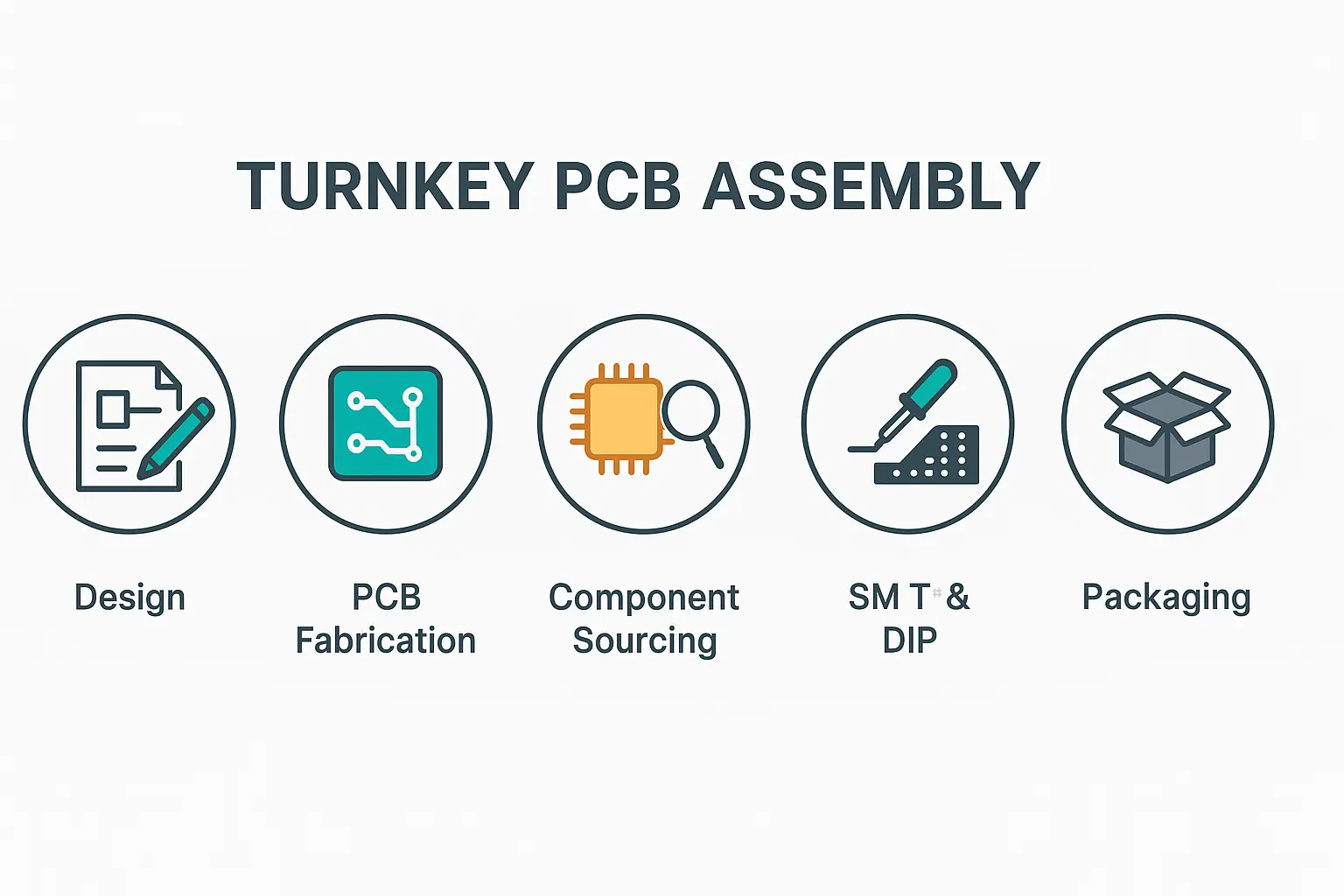

What You'll Receive

- EXW/FOB pricing structure

- OEM/ODM customization options

- Lead times and logistics info

- ISO/ROHS compliance documentation

Direct Contact

- +86 159 9957 7844

- info@txjpcba.com

- Shenzhen, China

GET EXW/FOB QUOTE

Enter your work email. We’ll send configurations, lead times, and logistics options within 1 business day.

Replies within 1 business day. Your information is confidential.