Although “printed circuit board (PCB)” is the most common term, “printed wiring boards” and “printed wiring cards” are also acceptable alternatives. Before PCBs, electrical circuits had to be built using the time-consuming method of point-to-point wiring. The insulation on the wires deteriorated and caused frequent failures at the connections and short courses. Let us check out the details of what is PCB.

What is PCB and Why It’s Essential in Modern Electronics

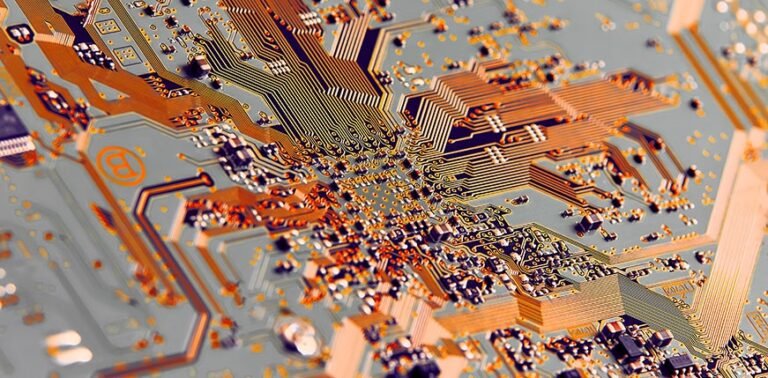

What is PCB? A printed circuit board (PCB) is the foundational building block of most modern electronic devices. It mechanically supports and electrically connects electronic components using conductive tracks, pads, and other features etched from copper sheets laminated onto a non-conductive substrate. Without PCBs, the compact and reliable electronics we use daily would not be possible.

In this article, we’ll explore the definition of a PCB, its types, functions, applications, and how it drives innovation in the electronics manufacturing industry.

Understanding the Basics of PCB

When we ask “what is PCB,” we’re essentially referring to a printed circuit board—a flat board made from insulating materials like fiberglass or composite epoxy. These boards are designed with etched copper pathways that guide electricity through a circuit to connect different components such as resistors, capacitors, and microchips.

PCBs replaced traditional point-to-point wiring, which was bulky and prone to errors. Their standardized layouts reduce wiring complexity, improve reliability, and enable mass production of complex electronic systems.

The Evolution of PCB Technology

To fully understand what is PCB, it’s important to explore its development over time. Early circuit boards in the 1930s and 1940s were manually assembled and used for military radios. After World War II, PCB usage expanded into consumer electronics, and by the 1980s, automation and surface-mount technology (SMT) became mainstream.

Today’s PCBs integrate high-density interconnects (HDI), multi-layer stack-ups, and embedded components, enabling the production of smaller, faster, and more reliable devices like smartphones and medical wearables.

Main Types of PCBs

There are several types of PCBs tailored for specific uses and environments:

- Single-sided PCBs – Only one side of the board has conductive material. These are used in simple devices like calculators and power supplies.

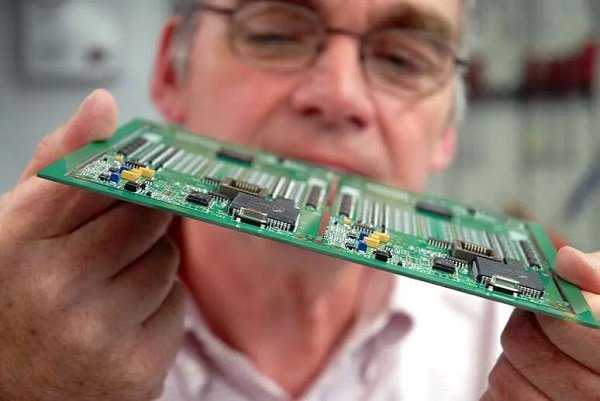

- Double-sided PCBs – Copper layers on both sides, with vias to connect them, offering more routing flexibility.

- Multilayer PCBs – Contain three or more conductive layers, often used in high-performance applications like servers and smartphones.

- Rigid PCBs – Made of solid material that doesn’t bend, used in most traditional electronics.

- Flexible PCBs – Built on flexible materials for dynamic or irregular-shaped applications, like wearable tech.

- Rigid-flex PCBs – A hybrid of rigid and flexible boards, offering both stability and flexibility in design.

PCB Manufacturing Process

The PCB manufacturing process begins with designing the layout using specialized software like Altium or Eagle. After that, the board goes through several steps:

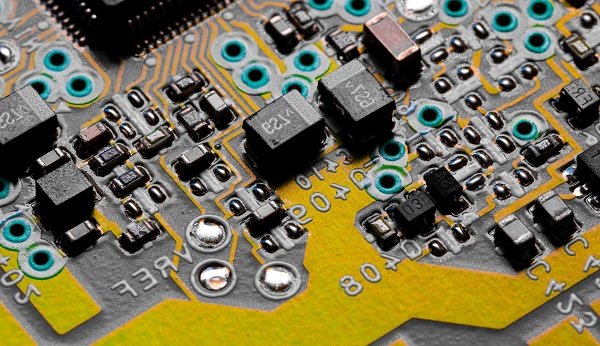

- Layer printing and copper lamination

- Etching to create the circuit paths

- Drilling and plating holes (vias)

- Solder mask and silkscreen application

- Surface finish for protection and conductivity

- Component placement and soldering (in the case of assembled PCBs)

Manufacturers like TXJPCBA ensure each step is precisely executed for high performance and durability.

Common Applications of PCBs

PCBs are at the heart of nearly every electronic product. Here are a few examples of their wide-ranging applications:

- Consumer Electronics – Smartphones, TVs, and home appliances

- Automotive Industry – Engine control systems, sensors, and infotainment units

- Medical Devices – Diagnostic machines, heart monitors, and portable devices

- Industrial Equipment – Automation controllers, robotics, and power converters

- Aerospace and Defense – Avionics, satellites, and communication devices

Key Factors in Choosing a PCB Manufacturer

When selecting a partner for PCB manufacturing, several factors can impact the success of your product:

- Technical capabilities – Can the supplier handle complex layer counts, HDI, or flexible PCBs?

- Quality standards – Look for certifications such as ISO 9001, UL, RoHS, or IPC Class 2/3 compliance.

- Turnaround time – Fast prototyping and on-time delivery are essential for agile development.

- Customization options – Support for custom stack-ups, special materials, and unique designs.

- After-sales service – Responsive engineering support and troubleshooting guidance

A reliable manufacturer like TXJPCBA ensures not only high-quality boards but also peace of mind throughout your product lifecycle.

Why PCBs Are Vital to Electronics Manufacturing

The introduction of printed circuit boards revolutionized the electronics industry. Their compact size, cost-effectiveness, and ease of mass production make them indispensable. Whether for simple gadgets or advanced computing systems, PCBs ensure precision, reliability, and scalability in design.

As technologies evolve, advanced materials and high-density interconnect (HDI) designs are pushing the boundaries of what PCBs can achieve. Companies that offer custom PCB fabrication and assembly services are critical partners for innovation in sectors like automotive, medical, and aerospace.

Conclusion

So, what is PCB? It’s more than just a green board inside your devices—it’s the silent workhorse that powers the modern digital world. From design to manufacturing, PCBs serve as the essential platform for every electronic circuit. Whether you’re a developer, engineer, or enthusiast, understanding PCBs is key to appreciating how our technology-driven world works.

If you’re looking for high-quality PCB solutions, TXJPCBA offers reliable PCB manufacturing and assembly services tailored to your project needs. Contact us today to learn more.