It’s no exaggeration to say that we are almost impossible to live a life without a printed circuit board (PCB). As a key component role of electronic assemblies, PCB is crucial for different walks of life. How many PCB application scenarios can you mention? Today, we share the 9 most common applications of PCB.

What is PCB?

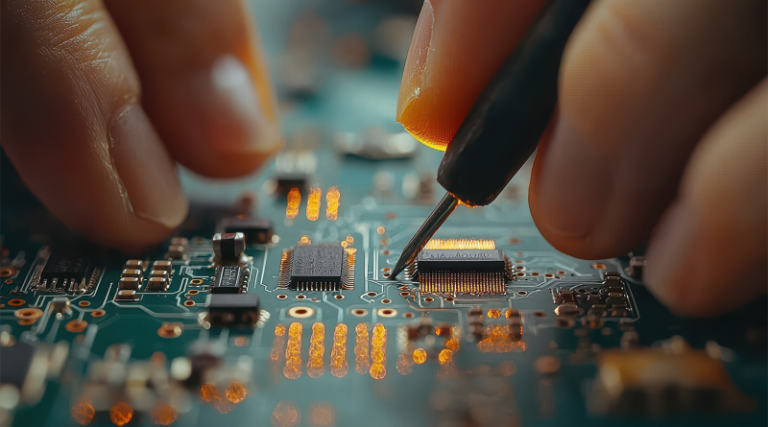

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They are flat boards made of non-conductive material, with conductive pathways etched or printed onto the surface to connect various electronic components. PCBs provide mechanical support and electrical connections, ensuring that electronic devices function efficiently and reliably.

9 Common Application Scenarios of PCBs

1. Consumer Electronics

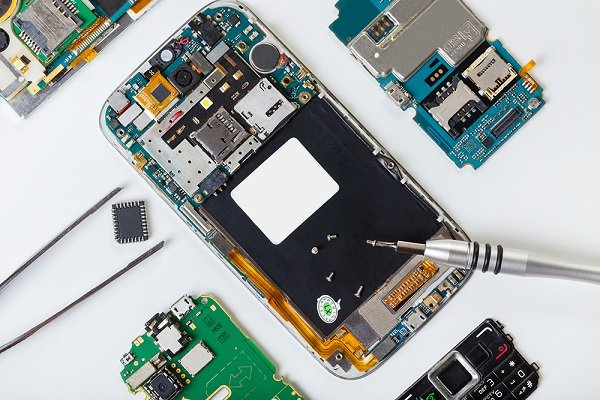

FPC, the abbreviation of the flexible printed circuit board, is a kind of PCB that takes polyimide or polyester film as base materials. Under the trend of intelligent and thin mobile electronic products, FPC gains traction with high density, light weight, thin thickness, bending resistance, flexible structure, and high-temperature resistance. You can find PCB as following consumer electronics.

- communication equipment: smartphones, tablets, smartwatches, and radios, etc.

- entertainment systems: televisions, stereos, and video game consoles, etc.

- household appliances: refrigerators, microwave ovens, and coffee makers, etc.

Living in a time-pressed era, we are occupied with a busy schedule in day life and the night when we can relieve ourselves by enjoying consumer electronics. Hence, the PCB applied to consumer electronics covers a great market share in the following years.

2. Automotive Industry

The components of automobiles also have a close relation with PCBs. Previously, PCBs were used for windshield wipers and headlight switches, but they enable them to be applied on advanced parts making driving safer currently. When it comes to driving safety, the manufacturer considers selecting high-temperature laminates, aluminum or copper substrates, or through-hole mounted components. This is why flex-rigid PCB attracted more attention. Try to find the PCB in your automobile.

- entertainment and navigation systems: stereo systems;

- control systems: engine management systems and fuel regulators;

- sensors: AD811ANZ sensors, obstacle detection sensor;

PCB is of importance for automobile components and has wide usage in the future.

3. Medical Devices

Health is always a heated discussed topic in public, which promotes the development of high-end and sophisticated medical equipment. Along with the advancement of technologies, medical device design has shown a multi-level and diversified trend, which has given rise to the diverse demands of medical device PCBs. For example, monitors, scanning technology, control systems, internal equipment, and scientific instruments are common medical PCB devices. They usually adopt a special high-density interconnector (HDI) PCB. Some common medical PCB devices are as follows:

- medical imaging systems: CT, CAT, ultrasound scanners, and the computers that compile and analyze these images

- monitors: Heart rate, blood pressure, glucose monitors, etc.

- infusion pumps: infusion pumps such as insulin and patient-controlled analgesia pumps.

- internal devices: pacemakers, etc.

Through equipment and instruments to assist doctors in detection, and improve accuracy and efficiency, PCB plays a dispensable role in improving the level of medical services.

4. Industrial Equipment

PCB applied in the industrial sector usually requires extremely high power and high durability to withstand harsh operating conditions. In order to meet these demands, the PCB ought to be made by durable metal and heat-resisting materials. Some applications in this field are as follows:

- fabrication equipment: electronic power drills

- power supply equipment: DC to AC power inverters, solar heat and power cogeneration equipment, etc.

- measuring equipment

With advanced technologies like IoT and robotics become pervasive, PCB used in industrial also derives different usages.

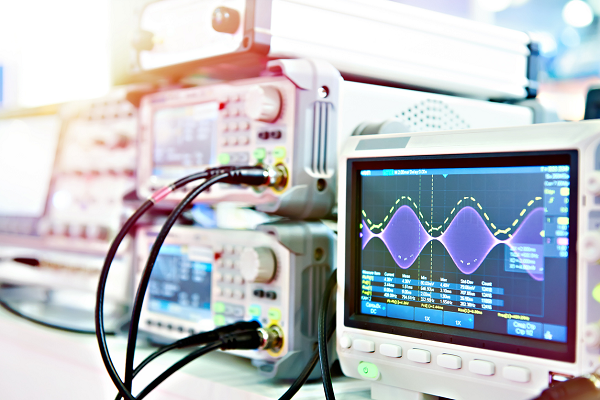

5. Telecommunications

PCBs are essential in routers, switches, and base stations, facilitating seamless communication and data transfer.

6. Aerospace industry

The aerospace industry has more strict requirements on the component which requires PCB to possess oxidation resistance and durability. PCB assembly with thermal management is the main USB of any operating system used by the aerospace industry. There is a compact layout for heat dissipation, which can carry out the PCB heat dissipation design. Highly customized, heavy-duty PCBs are critical to electronic devices used in aerospace. The usage of PCBs in the aerospace industry includes:

- power: aircraft, control towers, satellites;

- surveillance equipment: accelerometers and pressure sensors

- communication equipment

7. LED Lighting

LED is an abbreviation for Light Emitting Diode, which is a semiconductor diode. The LED is soldered to a PCB and fitted with a chip that creates light through electrical connections. As a widespread lighting technology, LED is not only used for residential and commercial lighting, but also included automotive, medical, and computer technology. Featured with high efficiency, long using lifespan, and compactness, LED becomes favored in the market.

What’s the role of PCB in LED? It can dissipate heat away from the bulb which expands the average using lifespan of LED. Therefore, PCBs for LEDs are usually made of aluminum, which transfers heat better than other metals and eliminates the need for additional radiators.

Where can we find LED PCBs in daily life?

- residential lighting: LED lighting like smart bulbs;

- storefront lighting: companies and shops used LEDs;

- automotive displays: dashboard indicators, headlights, brake lights;

- computer monitors: indicators and screen displays;

- medical lighting: LED light for surgery and other wards;

Strength with lower power consumption, compact size and environmentally friendly, LED PCB owns a large development space in the future.

8. IoT Devices

The Internet of Things (IoT) relies on PCBs for smart home devices, wearables, and sensors, enabling connectivity and data collection.

9. Power Supplies

PCBs are used in power supply units for various electronic devices, ensuring stable and efficient power delivery.

Conclusion:

PCBs are indispensable in the electronics industry, enabling the functionality and efficiency of a wide range of devices across various sectors. Understanding their applications helps in appreciating their role in advancing technology and improving our daily lives.